Legacy Obstacles vs. The Compliant, Data-Driven Maintenance Program

Recently I had a call with Brandon Wiseman of TruckSafe Consulting and one of the discussion topics was; "Where do I find fleets and carriers generally struggle with compliance the most?" While we will first discuss the root, the focus will be on MAINTENANCE.

For the root, I think a large portion of that answer can be prescribed to the level of industry intelligence and understanding that day-to-day carrier managers and especially Executives possess. Who are we hiring to manage our MOTOR CARRIER businesses? Most don't realize the collaboration that is required to manage a Motor carrier operation because they lack the industry knowledge that's required to understand that compliance in a transportation business reaches across all departments. Whether it is Human resources, Maintenance, Onboarding, Insurance, Legal, Claims, etc., it's all governed by compliance. Hiring a tax accountant with no knowledge of FMCSA to manage your national, Enterprise motor carrier fleet and operations is not the best decision and you'd know that if you knew the industry. That's one of the top reasons but even that can be remedied by the number one issue, solving the crisis that exists between self-reflection and change. Lack of knowledge leads to reliance on everyone else because you only know what others tell you.

Centuries ago people realized there has to be a better way. We couldn't use stone wheels forever. The industrial revolution changed and launched the world into a very different way of doing things. While the "Yodel Meter" and the "Dynasphere" were all the rage, some of those legacy traditions have become legacy obstacles. Those traditional ways of doing things are once again being molded by change, primarily through digitalization, data-driven processes, and technology-driven programs. For some, self-reflection to understand you're in the stone age of carrier operations, compliance, or fleet management is lacking often to the extreme. That lack of self-reflection merges with a mindset of the uncertain and our first instinct is to revert back to our traditional ways, i.e. chisel, stone, and hammer. Where is this most common? Executives to start. No Executive is ever going to go to the Board who hired him and say, "Hey, I don't fully understand how to run this business from a practical perspective. I understand numbers but I don't know how to look at an engine." (Don't even get me started on how that affects rapport with employees.) With that said, Fleet Managers are the most prone to fight against anything that requires change.

Let's talk about your traditional fleet maintenance program. FMCSA requires you to have a preventive maintenance program, but what is that and is yours adequate?

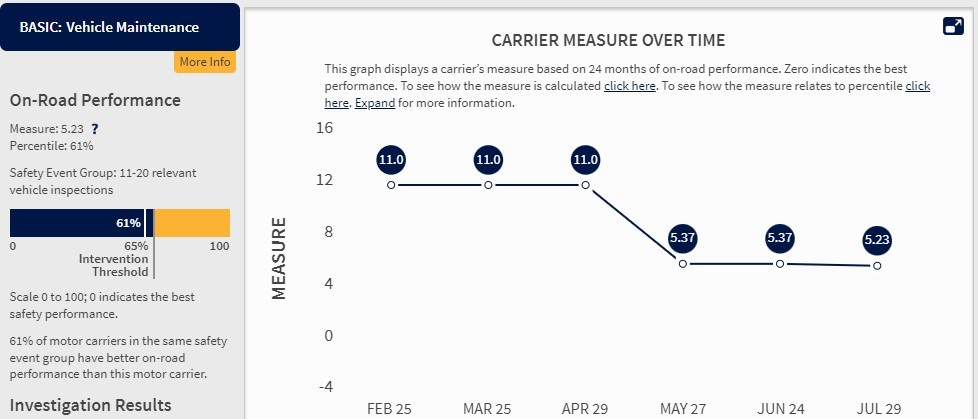

Preventive vs reactive maintenance program. Can you imagine if an airline only fixed their airplane fleet when the planes broke down or only replaced and serviced engines when they burnt up in the sky? I can't begin to tell you the number of highway fleets that operate in that reactive mindset of fleet maintenance. It's a fire so let's put it out and the success metric is driven solely by being able to keep wheels turning and vehicles on the road. That is a reactive, unsafe, uncompliant program with the worst performance indicator metric of all. This leaves you susceptible to violations, which turns into you exceeding your maintenance thresholds which leads to an intervention that leads to highly excessive civil penalties. Public perception then plays a role. Those violations and fines, threshold percentages are all public information by way of Safer/SMS. Brokers check this before they will give you a load, businesses check this before they'll award you a contract passengers can check this before deciding to ride.

Forget the traditional obstacles, change your mindset, educate yourself if you must, and move into the world of predictive maintenance. We all know profit margins for carriers are tight. They're even worse if you hire the wrong people to manage a business they know nothing about. One way you can alleviate the pain from hiring those people is by saving money elsewhere. It can start here and it can start big. Predictive maintenance, sometimes known as condition-based maintenance is a proactive, participatory maintenance program that eliminates reactive maintenance mindsets, keeps your vehicles on the road/reduces downtime, and saves you huge money on those reactive costs. Basically, you're tracking the health of your fleet in real-time and by using analytical data you're able to forecast when your fleet will need maintenance before a breakdown occurs.

Preventive maintenance relies heavily on human observation and is always necessary but it is driven by your policy intervals and schedules. The issue with preventative maintenance is it doesn't consider the condition of your fleet. Its purpose is solely to keep vehicles in running condition.

Predictive maintenance is dependent on a variety of data, both from human and electronic sources. This allows you to recognize and predict, possibly prevent, issues early onset. One of the most important keys to any maintenance program is a good pre/post-trip DVIR program. I personally prefer Motive's system (www.gomotive.com or Motive) because it provides you with full-time vehicle diagnostic information in addition to the frontline driver's routine inspection data. These can provide you with key data points that detect warning signs of potential failure which could include malfunctions, defects, or other issues that could disrupt your operations. The driver's observations and the tools currently available in systems like Motive or Fiix (Fiix by Rockwell Automation) allow you to minimize manual interaction by automating most diagnostic tasks. Modern technology is driving the way to a more modern, productive, data-driven, profitable fleet.

Customizable DVIRs, full-time diagnostics, reporting, and risk identification can push your maintenance program to the next level of compliance and reliability. This in turn will drive profit increases through more productive maintenance teams and facilities, more accurate budget forecasting, lower production costs, and reduction in operating expenses.

Some important questions to ask in assessing your maintenance program are; 1. What is your Mean time to repair? 2. What is your planned maintenance percentage? 3. What is your preventative maintenance compliance percentage? 4. What is your mean time to repair? 5. What is your mean time between failures? 6. What is your overall equipment effectiveness percentage? In today's data-driven, technologically advanced world, there's no reason you shouldn't be familiar with the fleet that drives your business in real-time.